Investments

RISK-OFF

-

Reduced flight delays and cancelations

-

Costs of maintaining stockpiles of spare parts are reduced

-

Technician labor costs are optimized

-

Engine availability is increased

-

Customer satisfaction increases

-

Flight safety is improved

-

The airline's reputation increases due to the introduction of innovative technologies

-30%

Number of

unplanned maintenance and repair work

+20%

The availability of airplanes

-22%

Maintenance and repair expenses

According to IATA

-50%

Number of flight delays

Lufthansa

-75%

Engine

maintenance time

Rolls-Royce

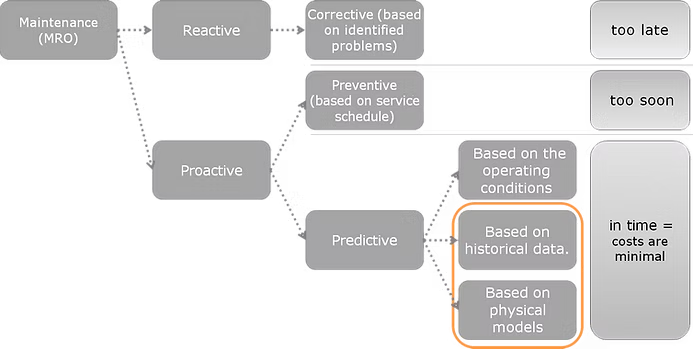

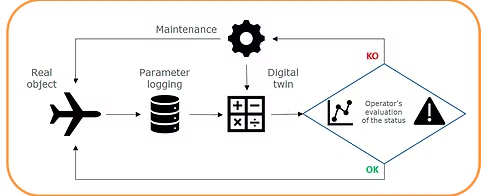

How does it work? General scheme of MRO

One of the methods to improve the accuracy of predictive model is to use modern methods of collecting and processing parameters based on calculations and historical data = data science.

The general pattern gives the idea that the more accurately we can predict the risk of a failure, the less it will cost the company.

Planning tool

The main tasks planned to be solved in the application:

- reduction of decision-making time for elimination of remarks by forming recommendations for action to technical services;

- determination of the technical condition of the engine (AC) by automated formation of diagnostic messages;

- forecasting of tendencies of change in the technical condition of the engine (aircraft).

General functions

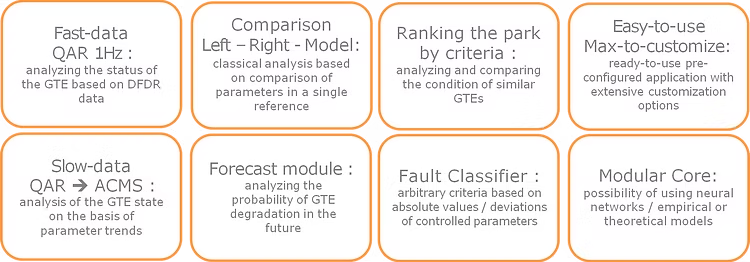

Diagnostics requires a variety of tools used to analyze the condition of the GTE, so the application includes the following basic functions implemented in graphical and tabular versions :

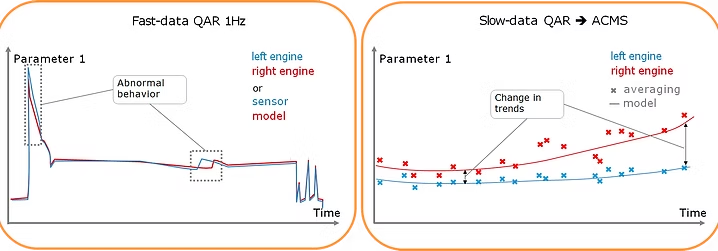

Principles of functioning

Fast-data / Slow-data

Analysis based on different intervals allows to identify local anomalies and control trends (degradation)

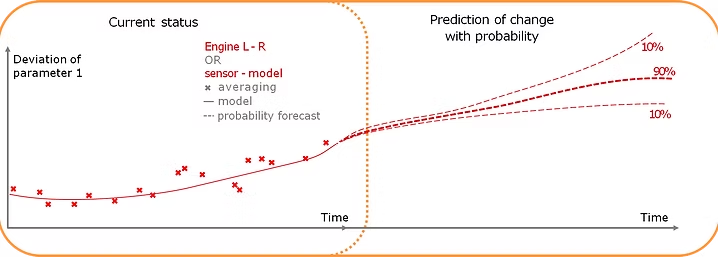

Forecast module

The ability to build trends of controlled parameters allows to forecast changes in the state of the GTE in the near future

Ranking by criteria

A

complete history of data processing allows you to display analytics,

categorize information and rank it according to user criteria.

Tracking changes in integral ranking parameters provides insight into MRO quality and trends.

Fault classifier

Due to the variety of interpretations of the deviations considered, the fault classification tool is as flexible as possible and allows them to be entered in any convenient way.

Universal approach.

Data systematization

Application structure

The web application consists of a server and a client part. The application requires:

- decoded parametric data,

- information about maintenance events of the product.

The application performs daily control of new flight data and

maintenance information, on the basis of which the condition of the

product is monitored and the calculation models are updated.

Calculation structure

Digital monitoring of UAV status

1) Monitoring the UAV status

Smart monitoring collects and analyzes data from UAVs, compares indicators, ranks critical parameters and visualizes the state. → What does it give? Prediction of failures, reduction of downtime and increase in the service life of equipment.

2) Web application - lightweight but powerful. No installations - just a browser

Deploy the solution in your infrastructure or use cloud platforms – without losing functionality. → Why is this important? Quick start, data security and flexibility of scaling for any tasks.

3) Flexibility to suit your requirements

Our team doesn't just deliver a "boxed" product, but configures the system to your processes, sensors and business logic. → A solution that works exactly the way you need it to.

4) Competitive advantage - technological advancement for the future

We build in AI modules and an extensible architecture so that your system becomes smarter over time:

Industrial tasks

1) Predictive monitoring and maintenance of industrial equipment

What we do: We develop wear and failure prediction systems for energy, oil and gas, mechanical engineering, transport and medicine.

Why us: Experience in calculations and automation + data science skills = accurate models for turbines, compressors, machine tools.

2) Smart Grids and Load Management

What we do: Optimization of resource consumption for factories and buildings.

Why us: We know how to calculate complex systems + we can visualize data for operators.

3) Development and verification of mathematical models for any industry

What we do: We create custom mathematical models (statistical, physical, hybrid ML) for business tasks.

Why us: The team knows both physics and data science → not a “black box”, but interpretable solutions.

4) Automation of business processes through data-driven solutions.

What we do: Creation of a service for demand forecasting, routing, inventory management taking into account external data (weather, fuel prices, etc.).

Aviation and aerospace industry /// Automotive industry /// Turbomachinery /// Compressors, pumps /// Nuclear power /// Traditional and alternative energy /// Shipbuilding /// Chemical industry /// Metallurgy /// Biomechanics and medicine /// Construction /// Electronics and electrical engineering ///